Selection and application of flame retardants for PBT and PET engineering plastics

Flame retardant PBT and pet (linear polyester) PBT and pet are two important engineering plastics, which are widely used in the electronics, instrumentation and automotive industries. Their flame retardant products are used in components with high flame retardant requirements. Their flame retardant treatment is as follows:

(1) decabromodiphenyl ether, brominated polystyrene (BPS), brominated epoxy resin (BER), bis (tribromophenoxy) ethane, etc. are commonly used to add brominated flame retardants.

For example, adding 10%-15% bromine flame retardant and 3%-5% antimony trioxide can make PBT containing 30% glass fiber reach UL94 V-0 level, and the oxygen index can reach 27%-29%. When using additive flame retardants, attention must be paid to the dispersion in PBT and pet, the easy exudation, and the impact on the gloss and mechanical strength of polyester.

(2) Tri (dibromophenyl) phosphate (tdbppe) is commonly used to add brominated phosphate. Because the same molecule contains BR and P elements, it has halogen phosphorus synergistic effect. Flame retardant efficiency is very high in PBT and pet.

It should be noted that it is often added in the flame retardant treatment; Antimony trioxide is synergistic. If the oxygen index test is conducted, the limiting oxygen index will increase. However, in the oxygen rich test environment, Sb and P seem to have an antagonistic effect. Therefore, UL94 vertical combustion method is the most suitable method to evaluate the flame retardancy of the system.

Flame retardant PET is used as flame retardant fiber and fabric.

There are usually two methods: one is to use hexabromocyclododecane for flame retardant post-treatment of PET fabrics. This kind of fabric can be used as curtain, curtain, wall covering and other indoor decorative fabrics. Due to the post-treatment method, the flame retardant is easy to exude, and the handle and flame retardant durability of the fabric will be inferior.

The other is flame retardant modification by copolymerization These reactive flame retardant monomers are mainly brominated aromatic compounds, aryl phosphine oxide compounds, brominated aromatic phosphine oxide compounds, etc. As the flame retardant element becomes a part of the molecular center of oligomer, it has the advantages of long flame retardant effect, good hand feel and light resistance. It is the main flame retardant method for pet flame retardant fibers and fabrics in China.

This article is from PBT engineering plastics:http://www.jnylmzx.com/

-

04-13

PVC Engineering Plastics: how PVC plastic pipes are formed

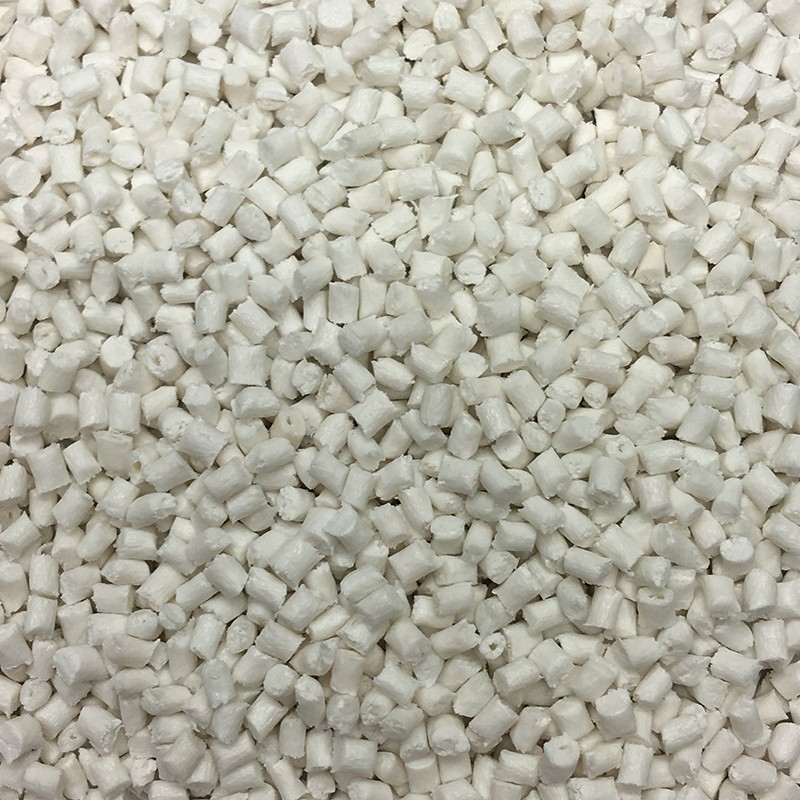

The forming process of PVC plastic pipes should start from the raw materials of PVC plastic granules, which can be divided into soft PVC and hard PVC according to the added amount of stabilizer, plast

-

11-12

What is the filling property of Jiangmen engineering plastics

What is the filling property of Jiangmen engineering plasticsIn recent years, PC modified plastics have developed rapidly in China, and its industrial system is gradually established and improved. Th

-

10-08

Jiangmen Engineering Plastics: how to classify Jiangmen engineering plastics?

How to classify Jiangmen engineering plastics? 1. Classification by application characteristicsAccording to the different application characteristics of famous plastics, plastics are usually divided

-

08-30

Application scope of PBT engineering plastics

PBT engineering plastics are widely used in electronics, car industry, office machinery and other fields. In Japan and the developed countries in Europe, PBT engineering plastics are mainly used in t