Analysis of Jiangmen engineering plastics processing flow of plastic products

Production process of plastic products

According to the inherent function of plastics, it is a complex and profound process to make them into plastic products with certain shape and application value. In the production of plastic products industry, the production system of plastic products is mainly composed of four successive processes: plastic molding, machining, decoration and installation.

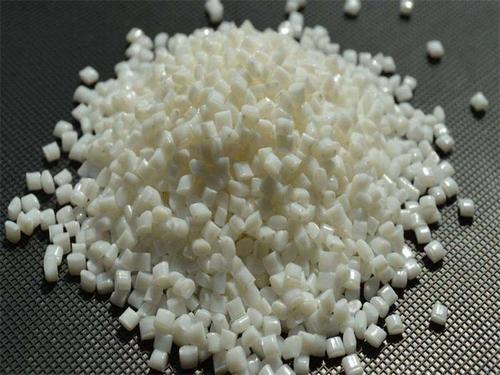

In these four processes, plastic molding is the key to plastic processing. There are more than thirty methods of forming. The first one is to make plastic of various shapes (powder, granule, solution or dispersion) into products or blanks of required shapes. The forming method mainly depends on the type of plastic (thermoplastic or thermosetting), the initial shape, and the shape and size of the product. Common methods for processing thermoplastic plastics include extrusion, injection molding, calendering, blow molding and thermoforming. Generally, molding, transfer molding and injection molding are used for processing thermosetting plastics. Lamination, molding and thermoforming are the process of forming plastics on a flat surface. The above plastic processing methods can be used for rubber processing. In addition, there are casting with liquid monomer or polymer as raw material. Among these methods, extrusion and injection molding are the most commonly used and the most basic molding methods.

The mechanical processing of plastic products is to use the plastic processing methods of metal and wood to manufacture plastic products with accurate scale or small quantity. It can also be used as an auxiliary process for molding, such as sawing of extruded profiles. Because the function of plastic is different from that of metal and wood, plastic has poor thermal conductivity, low coefficient of thermal expansion and modulus of elasticity. When the pressure of fixture or tool is too large, it is easy to cause deformation. When cutting, it is easy to melt and adhere to the tool. Therefore, when machining plastics, the cutting tools used and the corresponding cutting speed should be used to the characteristics of plastics. Common machining methods include sawing, shearing, punching, turning, planing, drilling, grinding, polishing, thread machining, etc. In addition, plastics can also be cut, punched and welded by laser.

The method of joining plastic parts by welding and bonding. Welding method refers to hot-air welding with electrode, hot-melt welding with hot electrode, high-frequency welding, conflict welding, induction welding, ultrasonic welding, etc. Bonding method can be divided into flux, resin solution and hot melt adhesive bonding according to the adhesive used.

The intention of plastic products' appearance retouching is to beautify the appearance of plastic products, which usually includes: mechanical retouching, that is, using filing, grinding, polishing and other processes to remove burrs and burrs on the parts, and correcting the dimensions; Finishing, including coating the surface of parts with paint, brightening the surface with solvent, and pasting the surface of products with striped film; Painting, including painting, printing and hot stamping; Metal plating, including vacuum coating, electroplating and chemical silver plating. Plastic processing hot stamping is to transfer the colorful aluminum foil layer (or other striped film layer) on the hot stamping film to the workpiece under heating and pressure. Many household appliances, building products and daily necessities use this method to obtain metallic luster or wood grain patterns.

Installation is the operation of assembling the finished plastic parts into complete products by means of bonding, welding and mechanical connection. For example, plastic profiles are assembled into plastic window frames and plastic doors through sawing, welding, drilling and other processes.

Source: Jiangmen engineering plastics http://www.jnylmzx.com/

-

04-13

PVC Engineering Plastics: how PVC plastic pipes are formed

The forming process of PVC plastic pipes should start from the raw materials of PVC plastic granules, which can be divided into soft PVC and hard PVC according to the added amount of stabilizer, plast

-

11-12

What is the filling property of Jiangmen engineering plastics

What is the filling property of Jiangmen engineering plasticsIn recent years, PC modified plastics have developed rapidly in China, and its industrial system is gradually established and improved. Th

-

10-08

Jiangmen Engineering Plastics: how to classify Jiangmen engineering plastics?

How to classify Jiangmen engineering plastics? 1. Classification by application characteristicsAccording to the different application characteristics of famous plastics, plastics are usually divided

-

08-30

Application scope of PBT engineering plastics

PBT engineering plastics are widely used in electronics, car industry, office machinery and other fields. In Japan and the developed countries in Europe, PBT engineering plastics are mainly used in t